Information

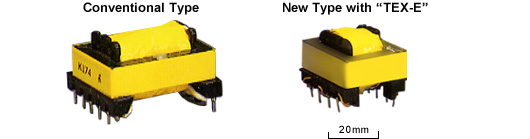

Triple Insulated Wires “TEX-E Series” have a prominent feature: no need of interlayer insulation tape or barrier tape between the primary and secondary coils of a transformer. This positive feature of TEX-E serves to downsize switching transformers, and promises high production efficiency and cost reduction. “TEX-E Series Wires” paves the way to the design of the most modern switching transformers.

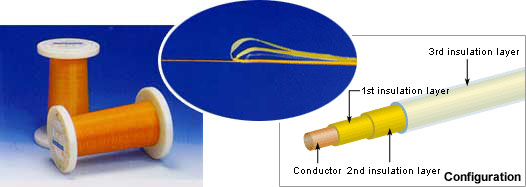

Unlike enameled wires, 3 layers of insulation of patented design are extruded over the copper conductor. IEC60950 requires some Reinforced Insulation between the primary and secondary coils. Thus enamelled wire transformers can never omit the insulation tape or barrier tape: enamel coatings give poor electric insulation. In contrast, TEX-E can form primary and secondary coils without a need of barrier tape or interlayer tape in-between. Each TEX-E wire is equipped with a three-fold insulation around the conductor, which has been authorized as Reinforced Insulation. As a result, the creepage distance can never be limited and no insulation barrier is needed, when specifying distances between termination pins and coils.

TEX-E has been in the market for more than 12 years. Today we have more than 2,500 TEX-E customers over the world, as a proof of the safe and steady performance of our wire products (TEX-E Wires). Their applications cover most switching transformers, information & telecommunications equipment, game machines, consumer goods, inverters and other similar devices.

Applied Commercial Devices & Instruments

- SMPS for units of Printer, Facsimile, Memory, Computer, Monitor, Inverter, Game Machine

- Battery Charger for assemblies of Digital Camera, Portable Telephone, 8mm VCR, AC Adapter, Personal Computer, DVD

- Operating Frequencies: Typically 85 kHz to 200kHz but level with a maximum of 500kHz

Features of TEX-E

- Certified as Reinforced Insulation; the combination of any two layers can resist up to 3,000 ACV for one minute.

- Falling into Thermal Resistance A(105°C) to E(120°C). Soldered without any surface layer bared (stripped).

- Smoothly coiled by automatic coiling machines. Offering a wide size choice of 0.20mm (approx. #32 AWG) to 1.0mm (approx. #18 AWG).

Dimensions

A standard type wire in TEX-E series, is made up of a conductor and three insulation layers of modified polyester and thermal resistant resin. This was designed and developed to aid solderability and eliminating the need for stripping.

Color

The jacket insulation on TEX-E and TEX-ELZ wires are manufactured in yellow only. See the TEX-E Product Brochure for the sizes we carry and other technical information.

Stock

Wire Specialties currently stocks TEX-ELZ wires in 5 sizes:

- 7/0.10mm

- 7/0.15mm

- 7/0.20mm

- 7/0.25mm

- 7/0.30mm